About us

Always strive for quality and detail

Meet Our Factory&Team

Factory Process

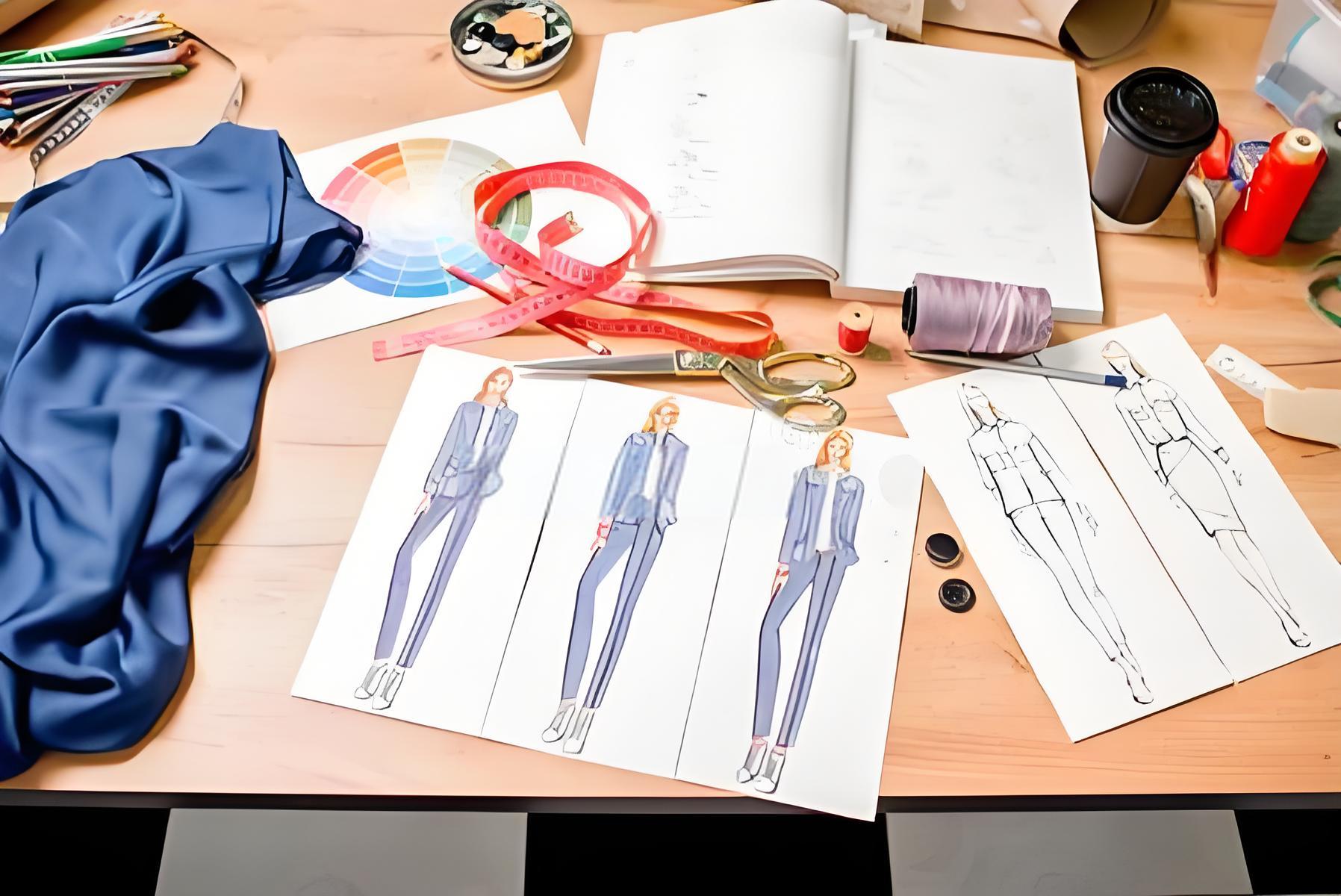

1- Design confirm

Before bulk order we will double re-check the styles all the details carefully, including style pattern, style request, style quantities, main fabric, lining, accessories, sewing technology, ensure all details are reviewed and implemented.

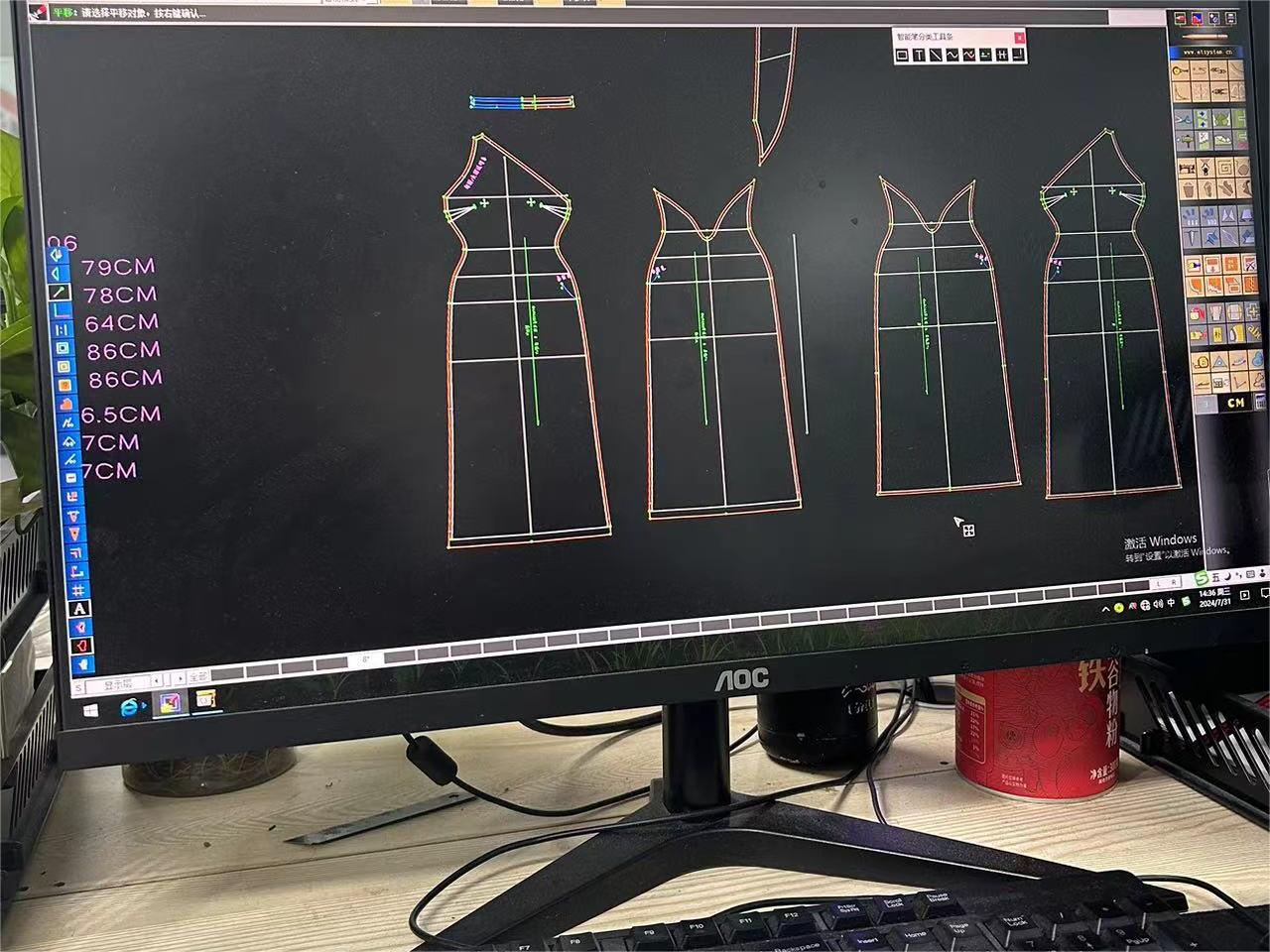

2- Pattern Grading

3- Production Sample

Before bulk we still have 1 more production sample. Follow exatly correct pattern, fabric, color, accessories, sewing techology. Review again and double confirm with clients. Elininate any small mistake.

Before bulk we still have 1 more production sample. Follow exatly correct pattern, fabric, color, accessories, sewing techology. Review again and double confirm with clients. Elininate any small mistake.

4- Check The Fabric/Accessories

All the fabric use on our client's styles we must check them all meter by meter, and accessores pcs by pcs, ensure them no quality issue, no color issue, no pattern issue. Avoid the mistake from beginning.

5- Fabric Shrinkage

Fabric preshrinking, as an essential processing technology, can not only improve the quality and reliability of the garment, but also ensure the stability and consistency of the garment size, and avoid deformation and shrinkage of the garment during the washing process.

Fabric preshrinking, as an essential processing technology, can not only improve the quality and reliability of the garment, but also ensure the stability and consistency of the garment size, and avoid deformation and shrinkage of the garment during the washing process.

6- Fabric Cutting

In strict accordance with the process, confirm the size, quantity, style, fabric front and back, fabric cutting direction, cutting way etc., make ensure that the cutting is accurate.

7- Garment Sewing

Work in groups and there is pre-production meetings before sewing, ensures high quality and also being efficient.

Work in groups and there is pre-production meetings before sewing, ensures high quality and also being efficient.

8- Ironing Clothes

In strict accordance with the ironing process and requirements, check the quality of each finished product, and according to different styles, different fabrics to adopt different ironing methods, temperatures. Make sure all parts of each garment are been iron in correct way.

9- QC Checking

we have team according to the company's product technical standards, process requirements, customer requirements, responsible for the product production process before, during and after each link of sampling work, make inspection records, to prevent wrong inspection, missed inspection, timely find the defective products in the product and mark, to prevent bad products, unqualified products mixed with qualified products and buried quality risks.

10- Product Packing

Clothing packaging is the outerwear of clothing, is an important part of the brand image. Therefore, when designing clothing packaging, it is necessary to pay attention to the requirements of brand characteristics, environmental protection of packaging materials, functionality and practicality of packaging, safety of packaging and cost control. Only in these aspects are properly considered and arranged, in order to produce high-quality clothing packaging, enhance brand competitiveness.

11- Warehouse and Transportation

Ensure the implementation of details and quality

1-Design link

1. In-depth understanding of market demand and customer preferences, combined with fashion trends for innovative design. In the design process, the practicality, comfort and aesthetics of the clothing are fully considered to ensure that the design scheme is in line with the trend and can meet the actual needs of consumers.

2. Repeated review and modification of the design drawings, paying attention to the design of details, such as the shape and size of the neckline, cuffs, pockets and other parts, as well as the location and collocation of decorative elements. Ensure that the design solution is technically feasible to avoid difficult design requirements in the production process.

2-Procurement of raw materials

1. Establish strict raw material procurement standards, and only select suppliers with reliable quality and environmental protection requirements. Strict quality testing of raw materials, including fabric strength, color fastness, shrinkage rate, quality and safety of auxiliary materials.

2. Establish long-term and stable cooperative relations with suppliers to ensure stable quality and timely supply of raw materials. Evaluate and audit suppliers regularly and urge suppliers to continuously improve product quality.

3-Production process management

1. Formulate detailed production process and operating specifications, and clarify the quality standards and operating requirements of each production link. Train employees to ensure that they are familiar with the production process and quality standards, and carry out production in strict accordance with the operating specifications.

2. Introduce advanced production equipment and technology to improve production efficiency and product quality. For example, the use of automatic cutting equipment can improve cutting accuracy and reduce waste; The use of computer embroidery machine can embroider more exquisite patterns.

3. Strengthen the quality control in the production process and set up multiple quality inspection checkpoints. Strict quality inspection in cutting, sewing, ironing and other links, timely detection and correction of quality problems. Strictly manage nonconforming products to prevent them from flowing into the next process.

4. Pay attention to details, such as the uniformity of stitches, the firmness of the binding of buttons, the smoothness of the zipper, etc. Fine treatment of the edges of the garment, such as wrapping, piping, etc., to prevent straying and wear. Pay attention to the interior details of the garment, such as the quality and stitching of the lining, the placement and sewing of the label, etc.

4-Staff management

1. Recruit employees with professional skills and experience, pay attention to the training and development of employees. Regularly organize staff to conduct skills training and assessment, improve staff's operation level and quality awareness.

2. Establish an incentive mechanism to reward employees with high production quality and stimulate their work enthusiasm and creativity. At the same time, strict accountability for quality issues to promote employees to pay attention to product quality.

3. Create a good corporate culture atmosphere and cultivate employees' teamwork spirit and sense of responsibility. Let employees realize that product quality is the lifeblood of the company and everyone is responsible for product quality.

5-Quality testing and after-sales service

1. Establish a sound quality inspection system to carry out strict quality inspection of finished products. Including appearance inspection, dimensional measurement, functional testing, etc., to ensure that products meet quality standards and customer requirements.

2. Provide quality after-sales service, timely deal with customer feedback and complaints. Analyze and improve the quality of customer feedback, and continuously improve product quality and customer satisfaction.

CATEGORIES

CONTACT US

Name: BTL Fashion

Mobile:+86 133 2640 1897

Tel:+86 133 2640 1897

Whatsapp:8613326401897

Email:admin@bethelclothing.com

Add:5th Floor, Building 7, ShiJing RongXi Industial Park, BaiYun District, GuangZhou